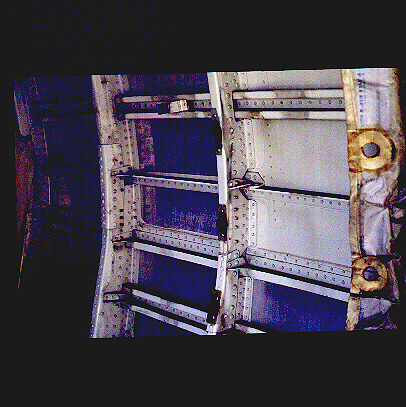

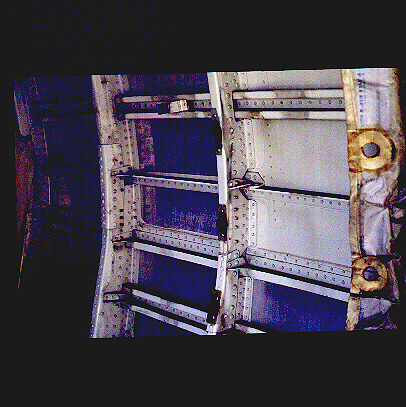

Here are some slides of several fuselage sections of a Boeing 727 showing the frames and stringers with different cross sectional shapes.

Slide #1: Notice in this slide the use of different shaped stringers in the fuselage. The top one is a hat, below it is an angle, below that is a Z, and at the bottom of the slide is another hat stringer. Also notice how closely (approximately 1") the rivets are placed next to each other.

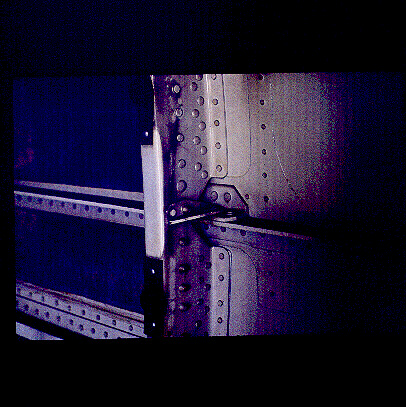

Slide #2: This is a close up view of a frame-stringer joint. Notice the use of a clip attaching the stringer to the frame. Also notice the use of skin doubler between the fuselage skin and the frame.

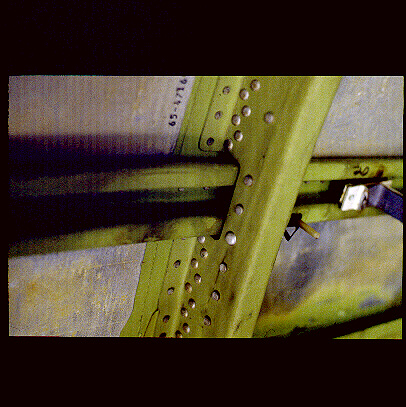

Slide #3: This slide shows what is commonly referred to as a "mouse hole" - the opening in the frame allowing the stringer to pass through it.

Slide #4: This slide shows the use of hat stringers in the fuselage section. Notice that the stringers are mounted with the top web as opposed to the flanges touching the skin. This form of attachment requires only a single row of rivets, whereas otherwise two rows of rivets would have to be used. This is a good example of how manufacturing requirements have been incorporated in the structural design.

To Index Page of

Internal Pressure

To Index Page of

Internal Pressure